TurnTables

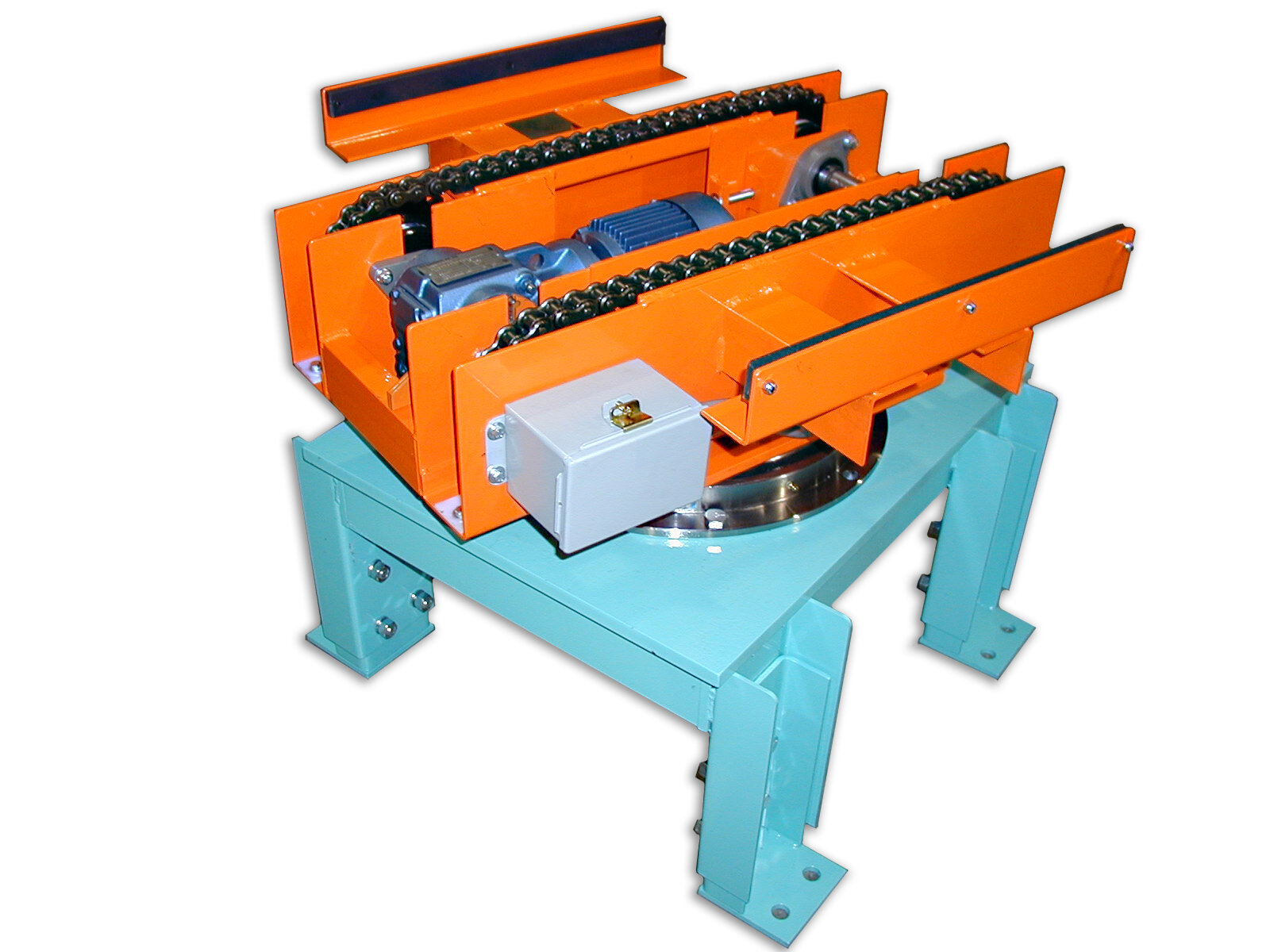

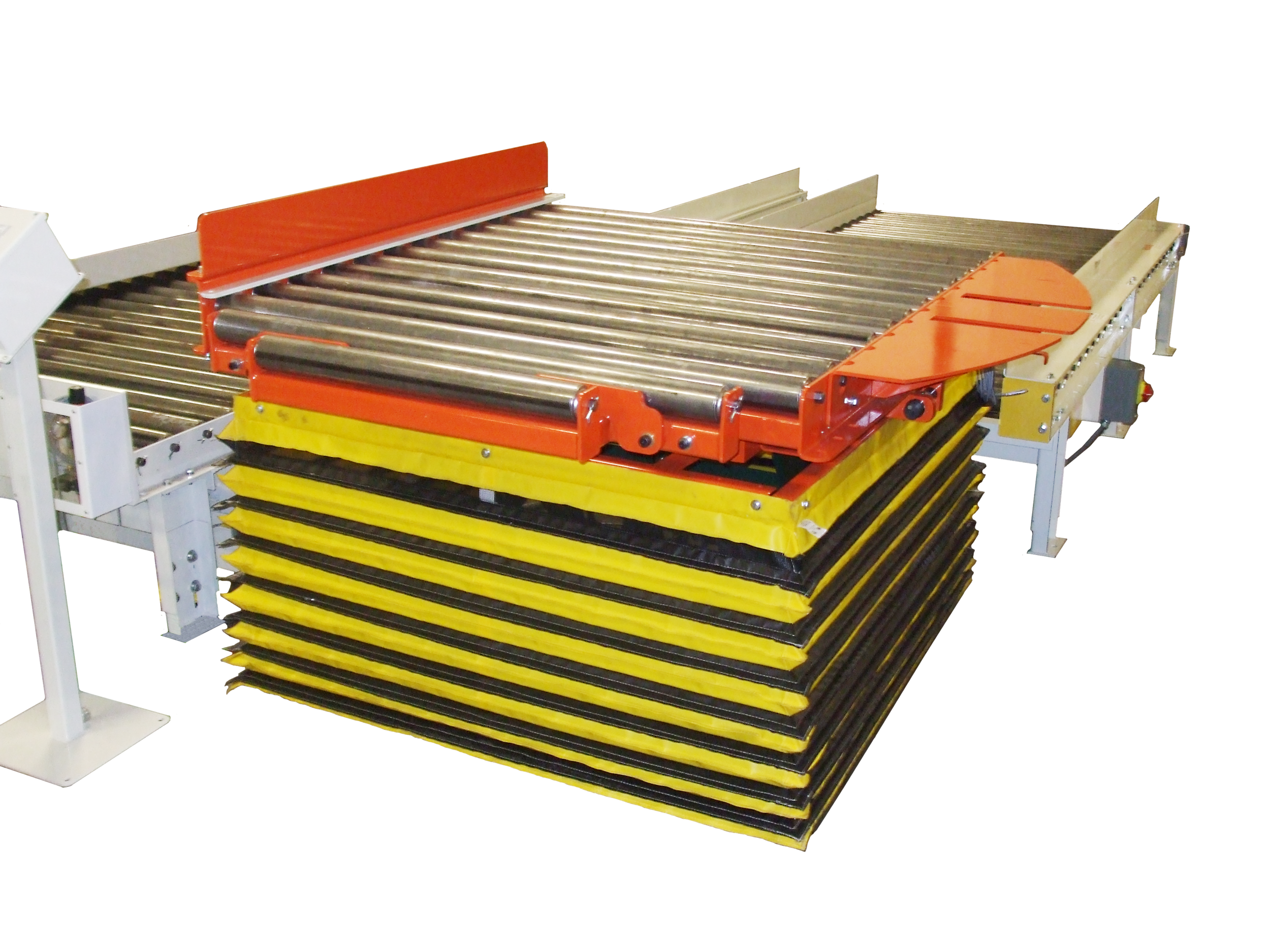

When designing a conveyor system, the main goal is always to figure out how to get the product from point A to point B. However, the product usually needs to be reoriented or rerouted before reaching point B. Turntables are designed and integrated to do just that!

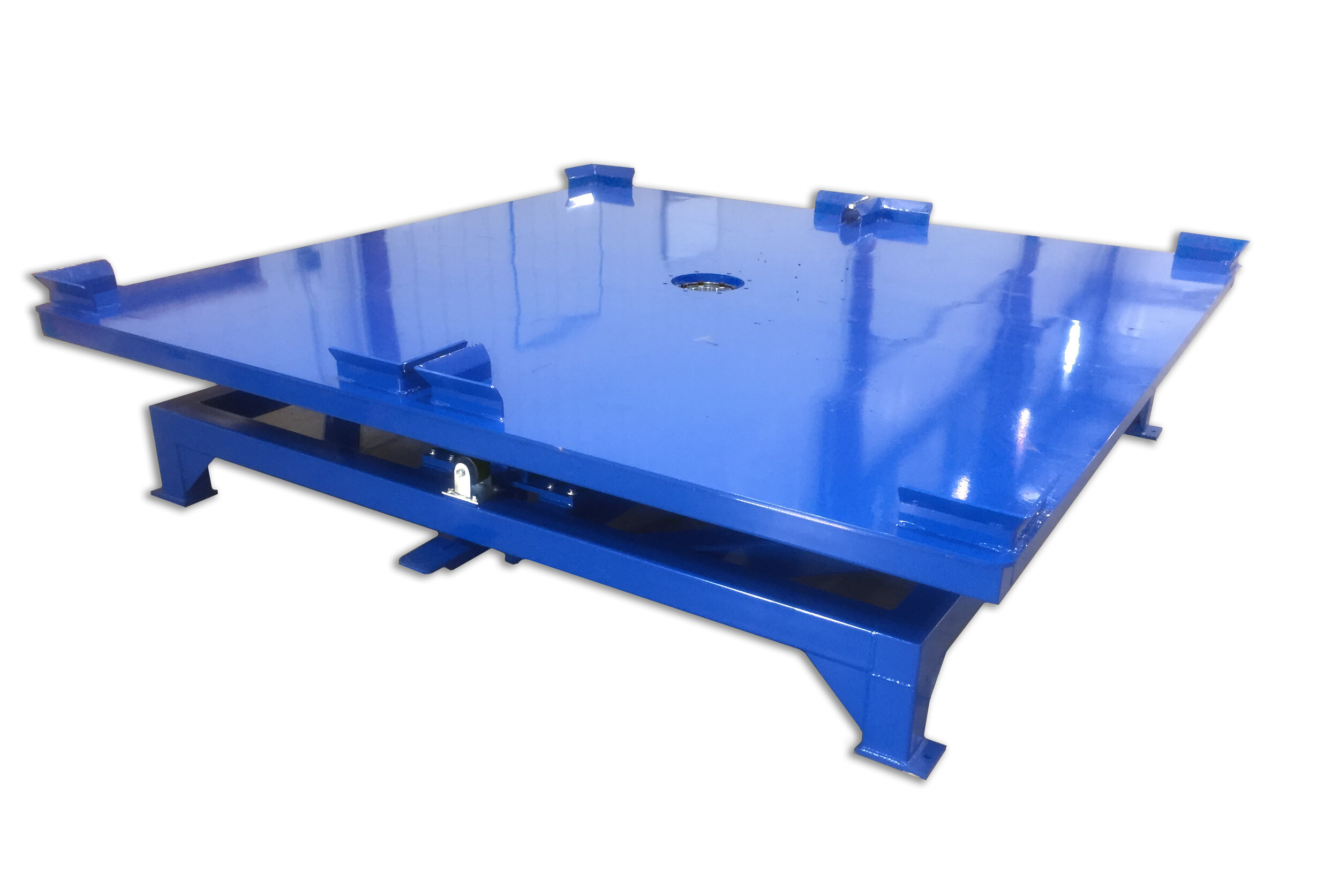

Integrating turntables into a conveyor system is a great way to reroute any product in various directions while saving space. In comparison, they can save more space (square footage) than conveyor curves or turns. This is mainly because turntables are able to pivot the product within the same singular footprint, where conveyor curves and turns require the product to be moving down the line in order for the reroute to occur.

Turntables are very common amongst even the smallest of conveyor systems. The biggest reason for this is because they come in a wide variety of different shapes, sizes, and styles. These different styles usually attribute to putting turntables into a wider variety of different price points, which helps companies make a decision on which turntable they need.

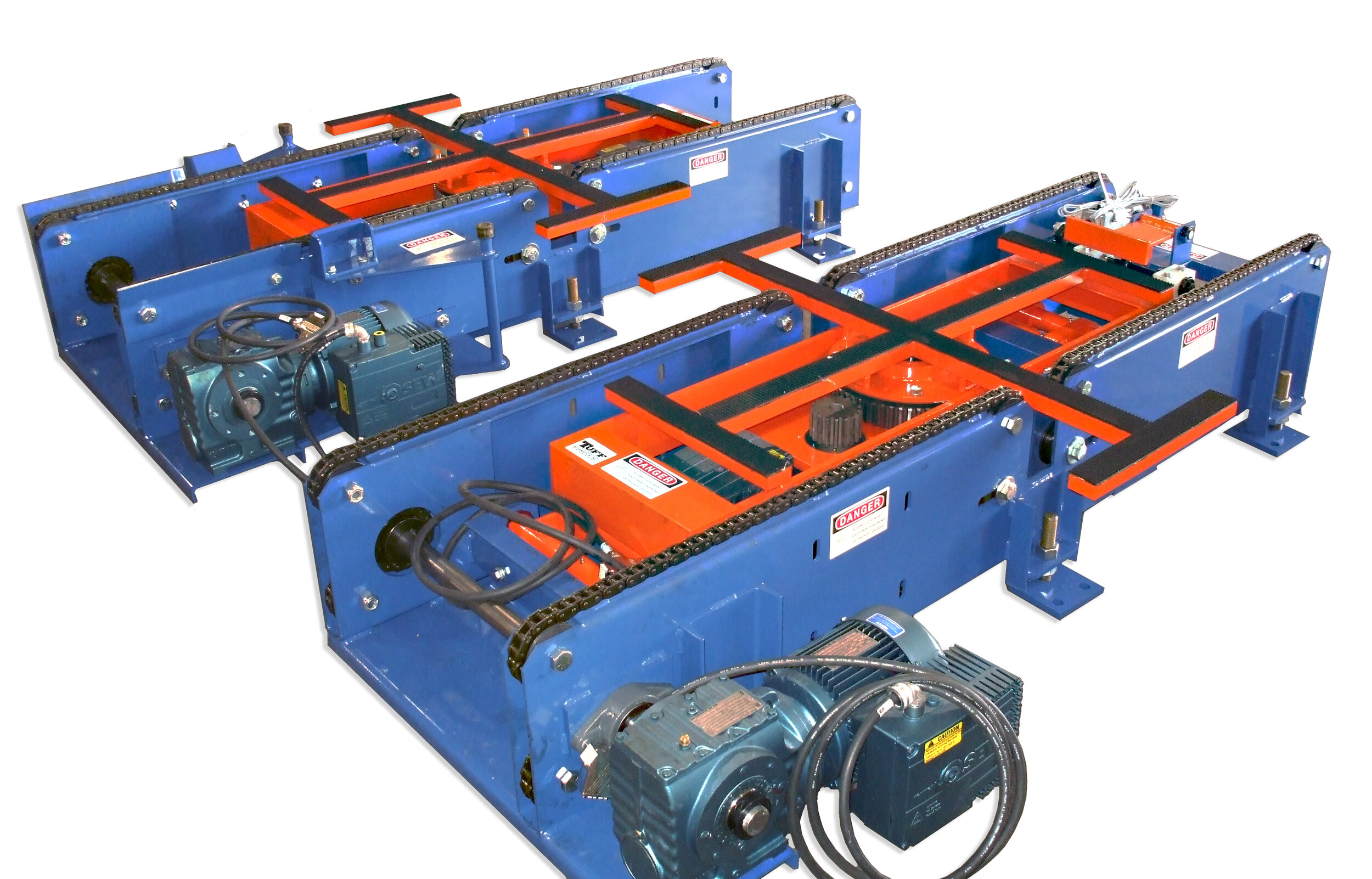

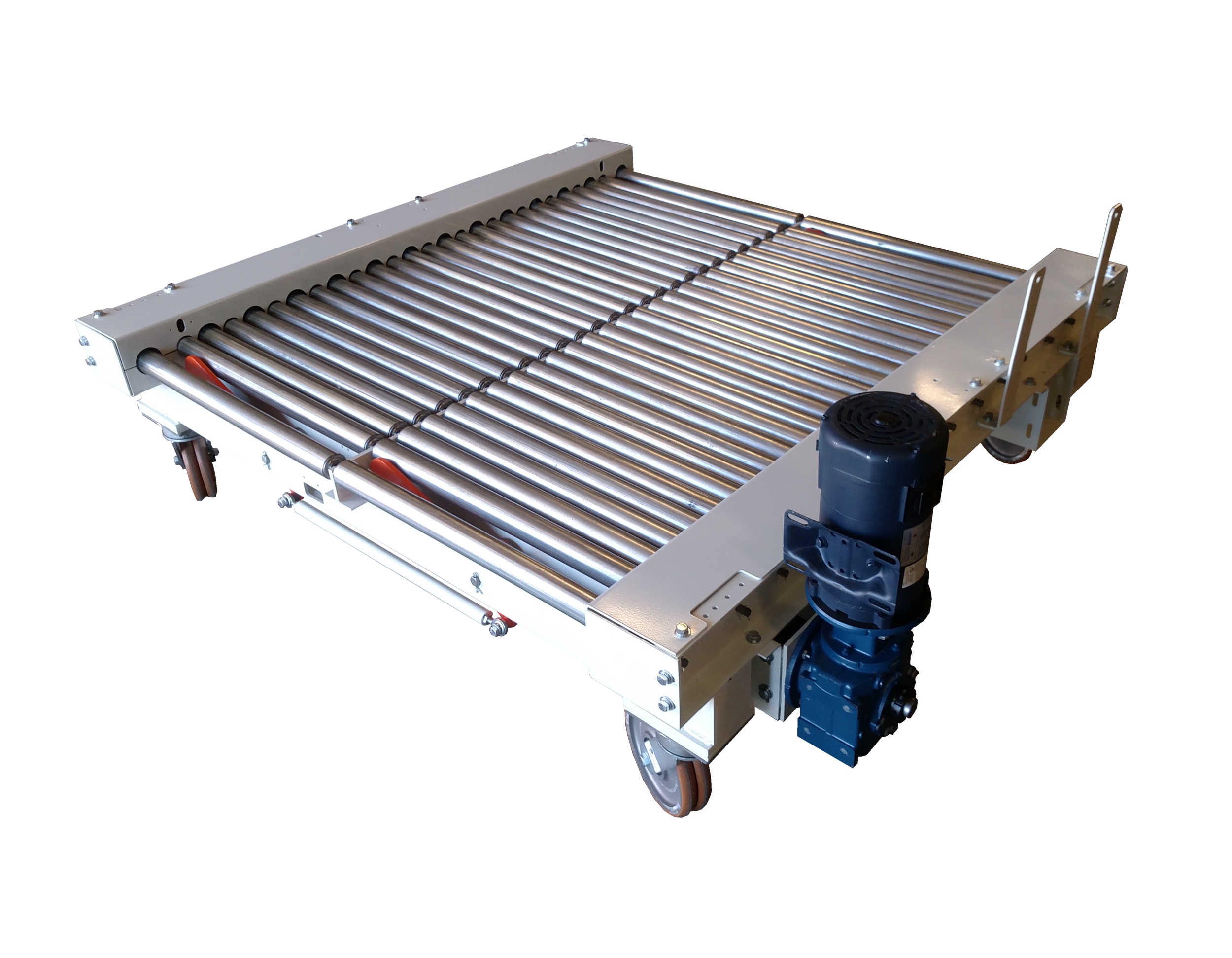

Here at Tuff Automation, we can design, build, and install turntables to be incorporated into any type of conveyor. We’ve designed turntables that incorporate chain and belt transfers, as well as, units that can be incorporated into gravity conveyors. With such a vast amount of experience, we’ve been able to create turntables with industry-leading features.

Key Features:

Belt, chain, gravity roller, or CDLR

Custom-made to any size requirements

Electric, pneumatic, or manual actuation

Constructed with highest quality materials

Durable formed steel construction

Painted to match any color

Heavy Duty Components

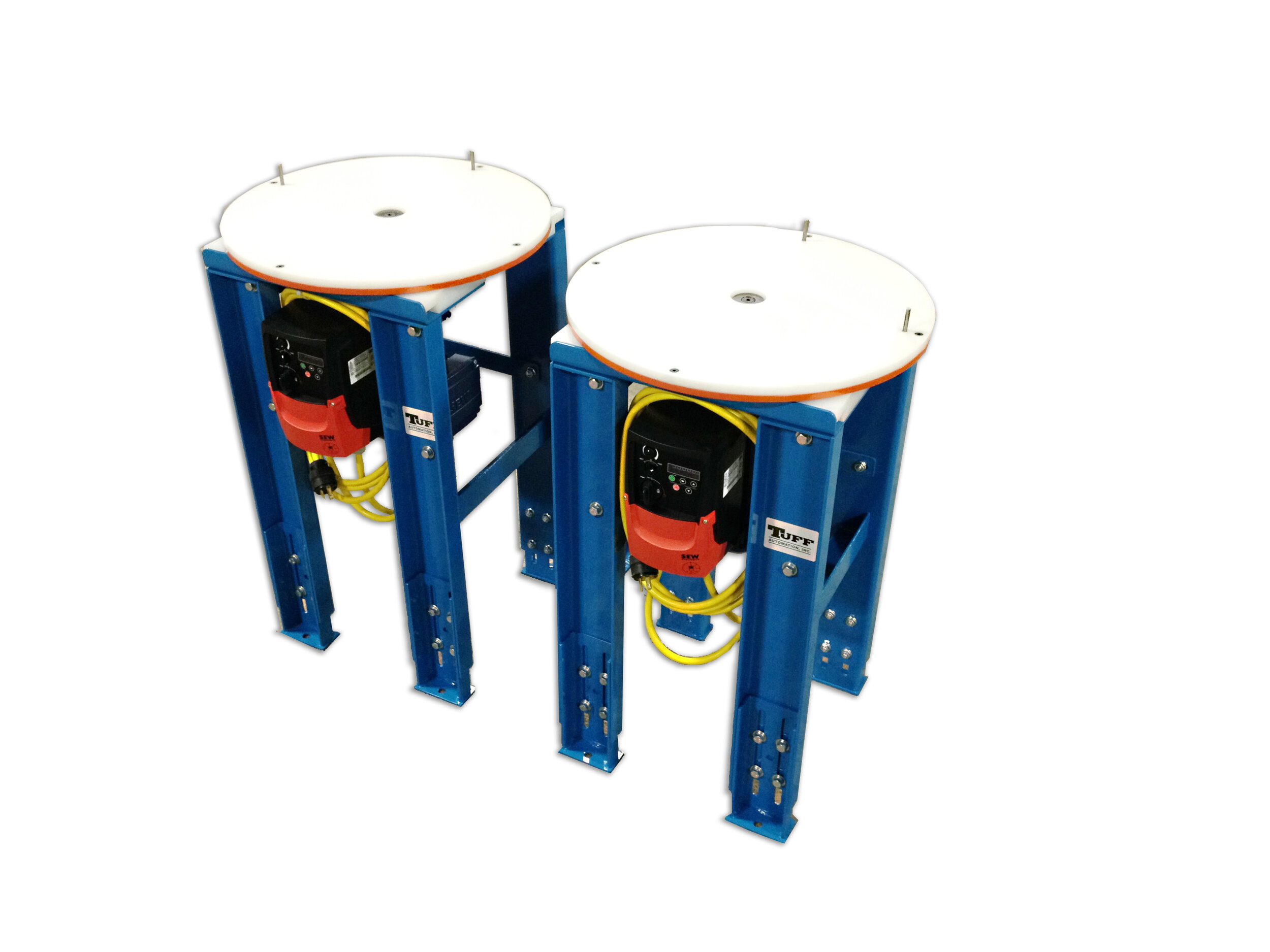

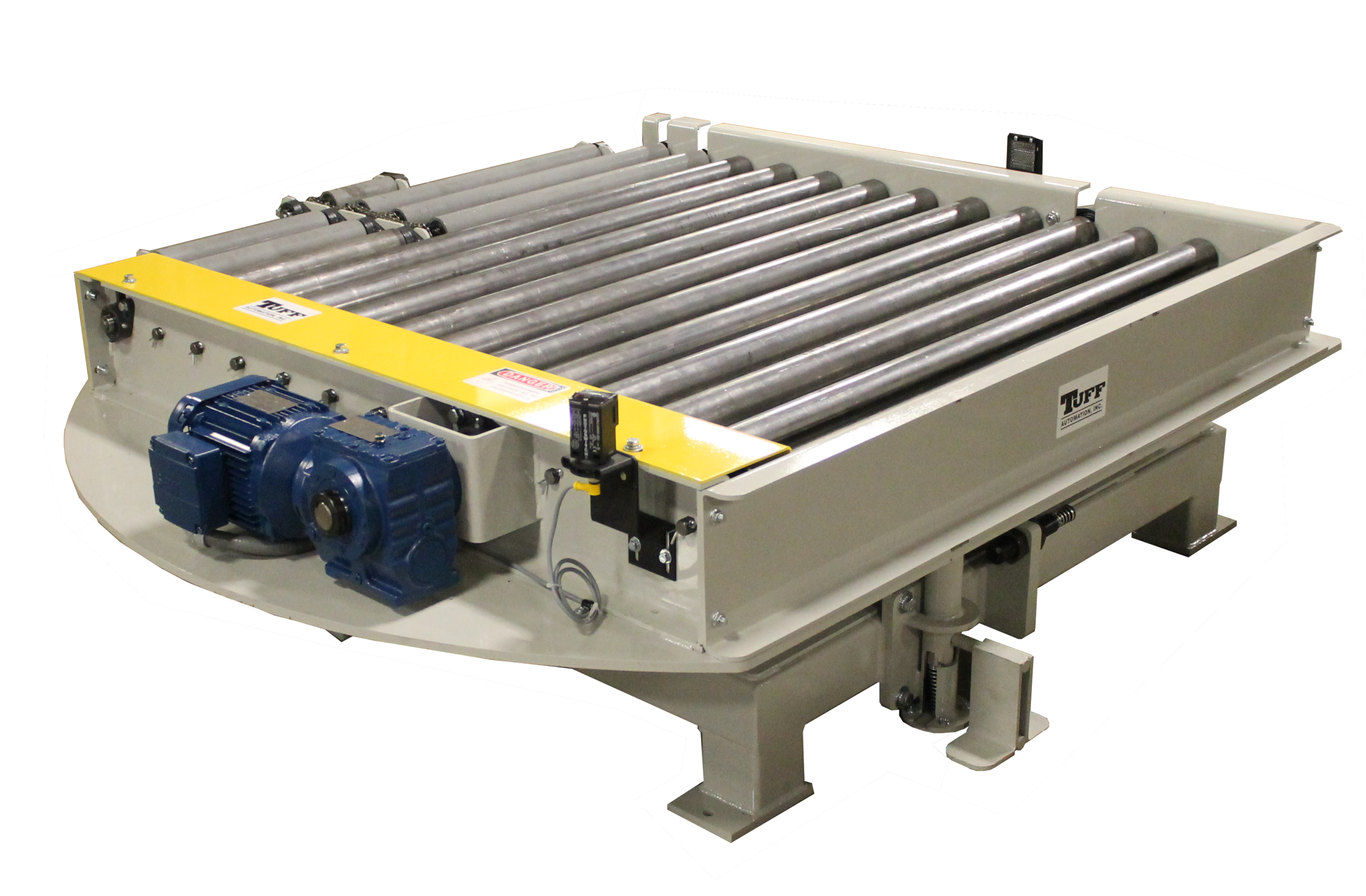

Rotate Stations

Another equipment option that should be considered when needing a product reoriented in a conveyor system is a rotate station. These are often identified and labeled as turntables, however, they are quite different in their design and are used in different applications.

A rotate station should be considered only when a product needs to be reoriented or rotated. A rotate station can be incorporated directly into a conveyor line so that it doesn’t take up any additional square footage.