automotive

We know You!

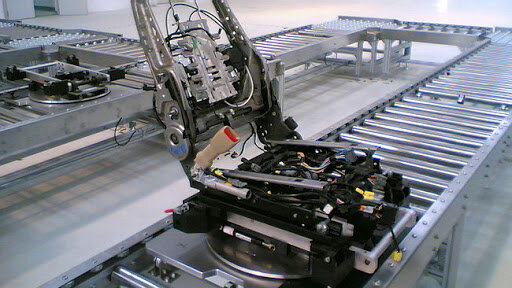

Our ability to design, manufacture, and install custom material handling equipment across the United States, has brought in numerous automotive assembly companies over the last few decades of our company’s lifespan. From seating to rotors, we’ve experienced and built a multitude of extensive systems to update the production of the world’s top automotive companies.

These experiences have enabled us to generate a positive reputation in the automotive industry. A lot of our automotive customers have continued to express how impressed they are by Tuff Automation’s ability to provide heavy-duty equipment for some very dense automotive part loads. This ability has also enabled us to provide custom equipment to help them stay up-to-date through an always evolving automotive culture.

For example, when it comes to automotive seating there are always changes being made to the product, which requires the manufacturers to adapt their production process, as well as, their system. Sometimes these can be minor adjustments. Other times, a complex custom solution is required to meet the customer’s expectations.

What do you need?

With an extensive backlog of projects to refer to Tuff Automation has a wide variety of different case studies to share!

Check some of them out here!